- Call Us

+91 98798 88877

- Email Us

info@sivmech.com

Quality

Quality Assurance

At SIVMECH COMPONENTS INC, we believe that the quality of the components we produce is, and always will be, performed and controlled by the individuals that physically produce them. Our quality approach is based on systems and controls that help the machinist and operators understand what our customers are asking for. Through education and a system of in-process cross checks, we are able to accurately produce in both prototype and production quantities the components that our customers need.

Quality Control Process

Careful measurement, inspection and testing are necessary to ensure the conformance of your parts. We perform multiple inspections at every step of the product development journey, from incoming material verification to final.

- Incoming Quality Control (IQC)

- Setup Approval Report (SAR)

- In Process Inspection (IPI)

- 100% Visual Inspection (VI)

- Pre-despatch Inspection (PDI)

CERTIFICATIONS

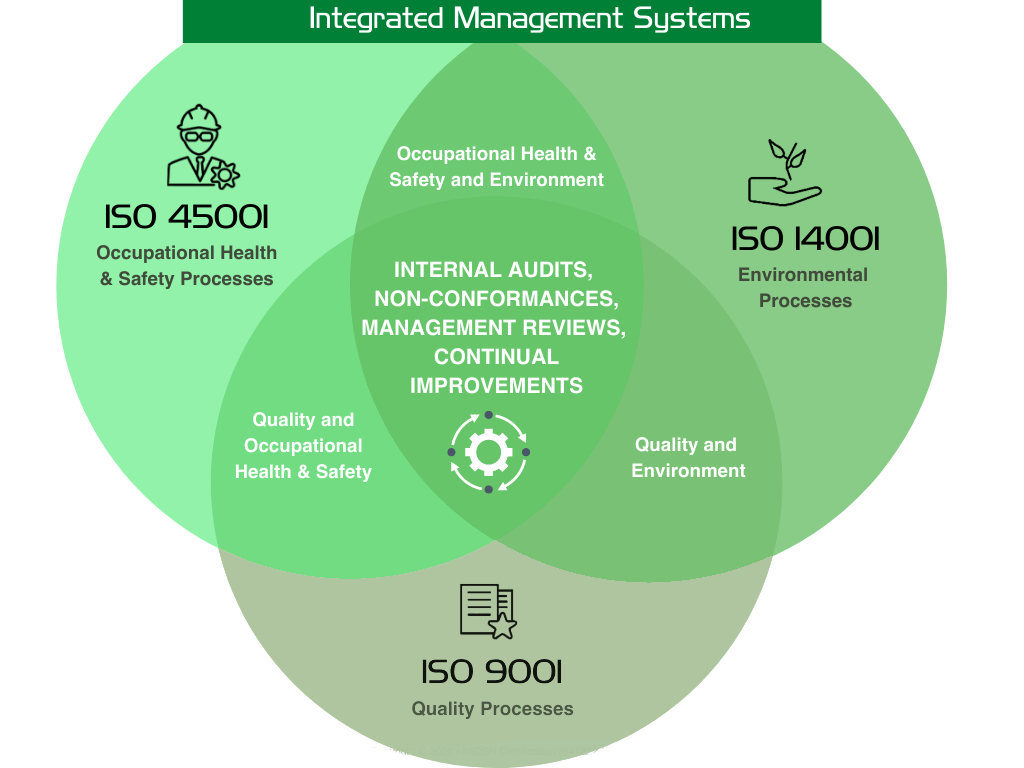

ISO 9001: 2015

Creates the framework for ensuring that all critical processes are fully documented, trained on and adhered to.

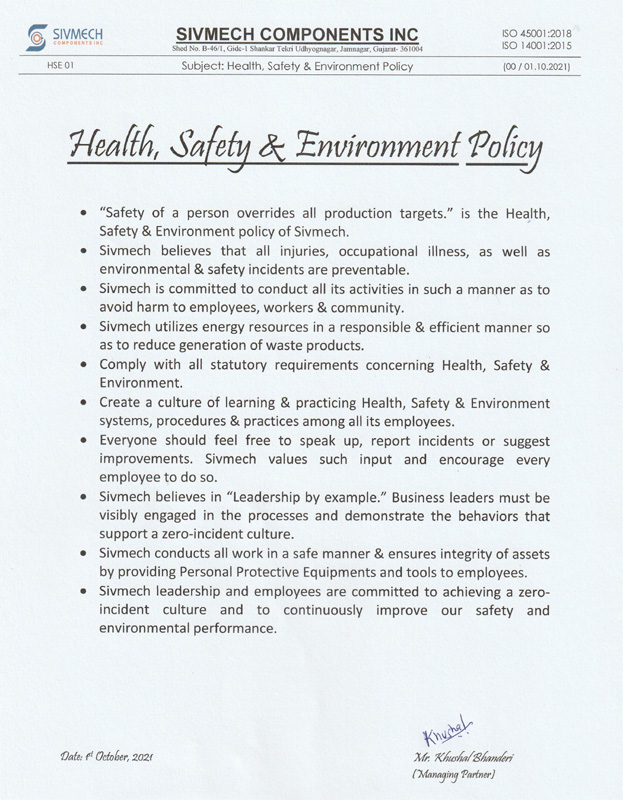

ISO 45001: 2018

Focuses on occupational health and safety. We are always working to protect the health of our staff and visitors.

ISO 14001: 2015

Controls our environmental management system. We take our responsibility seriously to be good stewards of the environment.

RoHS

Conforms the chemical composition and thereby restricts hazardous substances in all manufactured components.

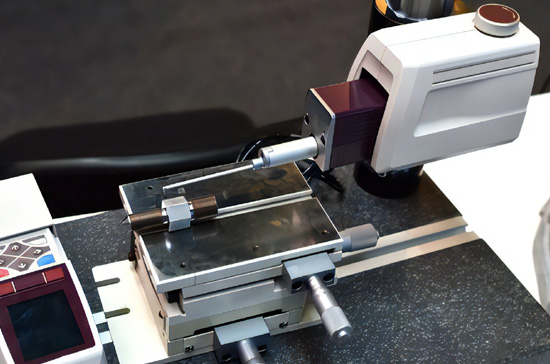

Measuring Instruments

SIVMECH COMPONENTS INC regularly practices scheduled calibration of quality measurement equipment and gauges, preventive and corrective action, control of non-conforming product, and in process and/or final inspection of product.